Efficient energy harvesting for low power automotive devices

28.01.2020

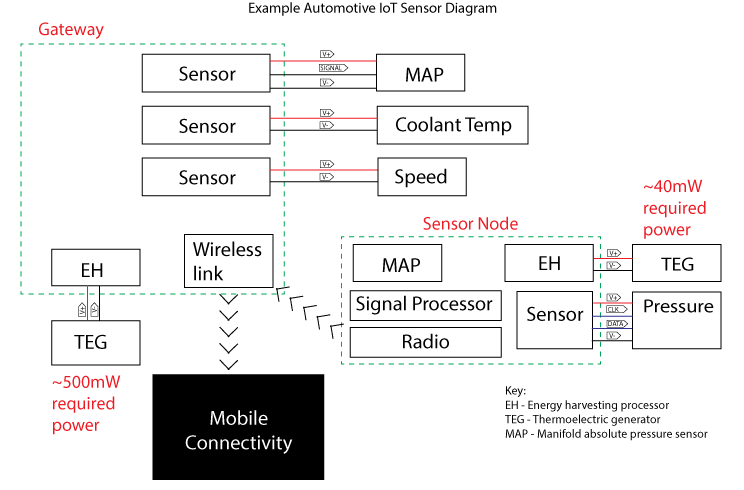

The image above shows an example automotive IoT sensor system configuration and depicts typical power requirements

Providing the Power for Automotive Connectivity

Customer expectations and EU legislation¹ have created a demand for vehicle-based, Internet of Things (IoT)-enabled connectivity. When carmakers equip vehicles with wireless mobile connectivity, this interacts with sensors and cameras to share and receive data via the cloud. Both with the dispersion of sensors across many elements of automotive design and the collection of ‘big data’ to facilitate intelligent functionality, many engineers are coming across the issue of how to provide power to these sensors and how to collect sensor information and forward for further processing through the internet.

¹https://ec.europa.eu/digital-single-market/en/news/ecall-all-new-cars-april-2018

Automotive IoT - Where Does the Energy Come From?

Gateways are network nodes, collections of sensors, sensor nodes and other electronic components equipped for interfacing with the internet.

With increasingly more electronics being designed into the car, a reliable, cost-effective source of power is often a barrier to successful design for IoT systems as they may be located in hard to reach areas such as within an embedded system, liquid container, or exhaust pipe.

Transmission of Data

Sensors often have an RF transceiver included to send data to a central hub, called a gateway, located a distance away. As well as sensors and sensor nodes, this gateway, usually including a transceiver and facilitating connection to the internet, will also require power.

Power Options

To provide power to sensors and other devices in an electronic system, options are limited:

Batteries

Batteries have limited operating temperature, size constraints, charging requirements and can be costly to replace in periods of maintenance.

Hardwiring

This has obvious limitations especially in hard to reach/ hazardous locations and also can be a costly method of connecting components.

Energy Harvesting

Design engineers will often look at a combination of the above power options alongside energy harvesting. This is discussed in more detail below.

Definition of Terms

Sensors

Sensors are sensing elements which translate physical measurements into an electrical signal.

Sensor Nodes

Sensor nodes are made up of multiple elements i.e.

- Sensor element

- Signal processing/microcontroller

- RF transceiver

- Power management

Gateways

Gateways are network nodes, collections of sensors, sensor nodes and other electronic components equipped for interfacing with the internet.

Energy Efficient Automotive IoT

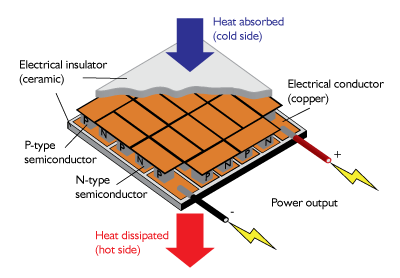

In automotive design as with all mechanical and electronic systems an inevitable amount of energy is lost as heat. Thermoelectric generators (TEGs) harvest waste heat. TEGs are especially useful power sources in hard to reach areas or in embedded systems where their solid-state nature means virtually no maintenance and compact design constraints. With up to 5% of heat energy harvestable in this manner, this contributes to an overall improvement in the system.

In automotive design as with all mechanical and electronic systems an inevitable amount of energy is lost as heat. Thermoelectric generators (TEGs) harvest waste heat. TEGs are especially useful power sources in hard to reach areas or in embedded systems where their solid-state nature means virtually no maintenance and compact design constraints. With up to 5% of heat energy harvestable in this manner, this contributes to an overall improvement in the system.

Milliwatts (mW) of power are required for most sensors. A typical low power IR temperature sensor would need 15mW of power. This could be achieved by providing enough temperature difference from the hot side to cold side of a TEG module, which additionally requires sufficient heat dissipation from the cold side. To provide suitable thermal coupling to air, a heatsink would be used. Alternatively, ultra-low power generation could be achieved using a lower temperature difference but using a number of modules in an array.

Today, thermoelectric technology works best where the power output required is up to 1W and at least a 20 degree C temperature difference can be achieved. This is suitable for sensors and other low power electronics in most types of industrial and automotive applications.

What are the Advantages of Using Thermoelectric Generators?

Fit and Forget

TEGs are ‘fit and forget’ solid-state devices especially suited to hazardous or hard to reach areas. As they harvest waste heat, they require no virtually no maintenance and no recharging.

Small and Lightweight

When compared to alternative technologies they are often smaller in size and weight.

Intelligent Adaptive Technology

Due to the ever-changing availability of harvestable thermal energy and intermittent power requirements of sensors, energy harvesting electronic circuit boards are used to intelligently boost and store the harvested power.

Optimised Power

A TEG plus energy harvesting board will provide optimum power to sensors or sensor gateways through using technology such as multi power point tracking, power boost, storage capacitors, and low OR-ing power rail controller.

Evaluating Harvested Energy

Evaluation Products

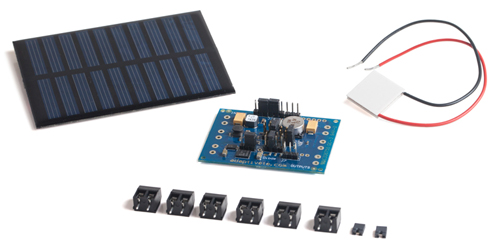

Under the Adaptive Power Management brand European Thermodynamics provide an energy harvesting kit with recommended products to assist design engineers and researchers for evaluation purposes.

The kit comprises:

- An energy harvesting board that features multi-power point tracking (MPPT) and power boost, storage capacitor and low loss OR-ing power rail controller.

- TEG module, ADPD-B - a 20 x 20 x 3mm, max. 2.5W thermoelectric generator for waste heat energy harvesting.

- A mini solar panel for photovoltaic energy harvesting (to allow full evalutation of the harvesting board and cross compatitbility).

- 2 shunts and 6 connectors

Specialist Miniature Thermal Energy Harvesting Devices

European Thermodynamics have a range of Adaptive® mini TEG modules available in sizes ranging from 11mm to 26mm. The main product attributes are their compact structure and suitability for use in high humidity environments in temperatures of up to 250 degrees centigrade. Power generated from these modules range from <0.42W (11 x 11mm module) to <2.37W (26 x 26mm module) dependent upon temperature difference achieved through the TEG module.

Graphs containing data of what power can be achieved at what temperature difference are available in the data sheet for each TEG module.

For more information visit our thermoelectric generator product page

The mini TEGs are recommended for use with the Micro-M Energy Harvesting Board. A 25 x 15 x 5mm energy harvesting board with MPPT, high-efficiency boost converter and low start-up voltage of 430mV.

Research and development

Continuous development work is essential for suppliers to continue to meet the technological demands of the sector. European Thermodynamics has active research programmes into lower cost, smaller footprint, more efficient thermoelectric materials, capable of operating at higher temperatures with the intention of lowering costs for future integration into vehicles and improving overall efficiency of vehicle systems.

European Thermodynamics Ltd is involved in collaborative research and development projects in both the UK and the EU (Horizon 2020).

Current and recently ended energy recovery R&D projects include:

VIPER2

Converting waste heat from automotive exhaust into electricity using a thermoelectric generator. Aiming for a 5% improvement in fuel economy through the conversion and management of heat energy

ATHLETE

Using an innovative semiconductor, Hafnium-free, half Heusler material to develop large waste heat recovery systems. These systems can achieve power generation of more than 500W.

DUET

Heavy-duty automotive market (buses, coaches and trucks) - developing new heavy-duty dual-fuel (natural gas and diesel) combustion and after-treatment technologies to meet future international legislation including future Euro VI+ emissions compliance with reduced carbon footprint at an acceptable cost.

ECOCHAMPS

Focusing on hybrid powertrain technology, recovering heat from the catalyst system.

JOSPEL

Focusing on the reduction of energy consumption by improving vehicle and battery efficiency of electric vehicles. This was done with a combination of effective thermal management and waste heat recovery from the exhaust and directing the resulting recovered electricity to improve zonal passenger comfort inside the vehicle.

About European Thermodynamics

Established in 2001, European Thermodynamics have a core competence in thermoelectrics and thermal management of electronics systems. As well as extensive research and development operations into improvements in thermoelectric materials, the company has a strong capability for engineering design in its own right and works with many OEM electronics systems designers to optimise their design performance through effective thermal management and/or active thermoelectric temperature management or power generation.

About the Adaptive® Power Management Brand

Adaptive Power Management is European Thermodynamics brand for high quality, reliable thermoelectric power management products including thermoelectric generators and energy harvesting electronics - to optimise thermal energy harvesting efficiency.

Adaptive Power Management is European Thermodynamics brand for high quality, reliable thermoelectric power management products including thermoelectric generators and energy harvesting electronics - to optimise thermal energy harvesting efficiency.